Inhaltsverzeichnis

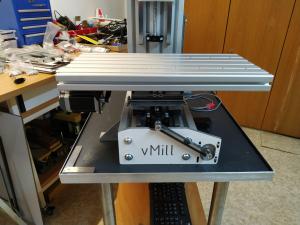

vMill

Since i followed Sebastian End's "Elke" build and watched talla83 retrofitting videos i wanted to build a vertical/console style CNC. The dream of a really rigid UHPC machine or a retrofit is still there, but shifted into the far future.

Since i followed Sebastian End's "Elke" build and watched talla83 retrofitting videos i wanted to build a vertical/console style CNC. The dream of a really rigid UHPC machine or a retrofit is still there, but shifted into the far future.

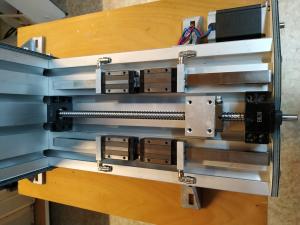

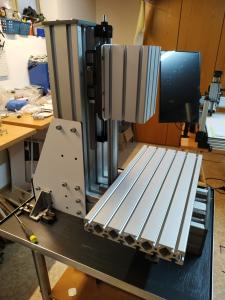

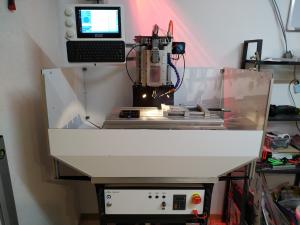

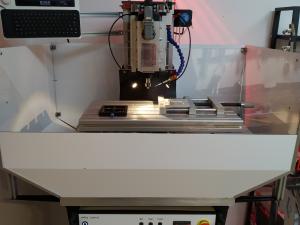

Stumbling along ebay i found a cheap set of 6 used 15mm linear rails. That in hands and some 1204 Ballscrews in stock i started drawing around a bit. Just before ordering some 180x90mm profiles a friend provided me with a really massive Robounits profile with 200x100mm. Great! Had to adapt my plans and cut the profile in pieces, but quite fast it started looking really good i think ;_)

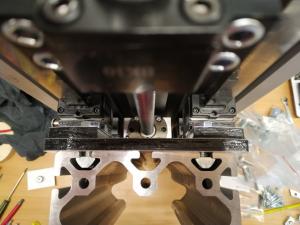

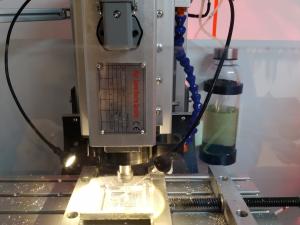

The machine table was build from 500mm of 240×40 profile, a small 120×120 profile was used to get the offset for the Z-Axis. All other parts were milled out of 8mm HPL, for some parts i had to glue 3 layers of that to get enough offset to fit the ballscrews between the rails. These parts will either be milled from Aluminum later on or i will order them laser-cut in steel.

The spindle will be the same as on my HTD-3M Belt Mill, as it fits quite nice to the 120×120 profile and i was available for cheap at this time.

Hardware Parts

Frame

- Robounits PIL 1020 200x100mm Alu Profil, 1×500,1x600mm gift from a friend!

- Aluminiumprofil 240x40 Nut 8 Schwer I-Typ 1x500mm ~50€

- Aluminiumprofil 120x120 Nut 8 I-Typ Schwer 1x190mm ~20€

- Slot Nuts and Srews ~50€

- Total ~120€

Linear Motion

- 15mm Heavy Linear Rails 340mm with 2/3 blocks each, 2nd hand from ebay 80€

- SFU1204 350mm with BK10/BK10 3x ~100€

- Total ~280€

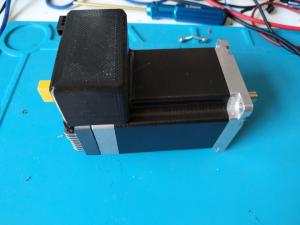

Controller

- 19„ Rack mount Case - 1994 Modem Unit i took from the trash ~10years ago.

- Celeron Motherboard with some RAM and an old SSD formerly used as my VDR.

- Emergency Switch, some Buttons, 2 SSRs and Power Plugs ~35€

- Total ~50€

Spindle

- VFD 1500W 220V ~66€

- Total ~210€

Links

Pics

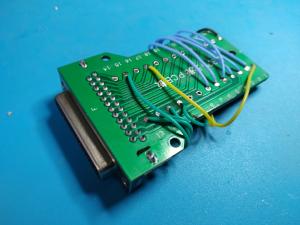

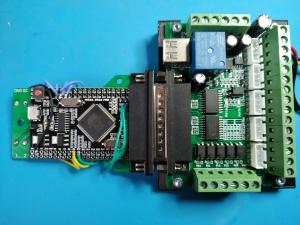

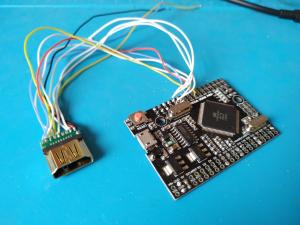

Controller

Estlcam

Videos:

Cutting the Estlcam touchplate out of 8mm Aluminum. 1/8“ single flute bit, 1500mm/min, 1mm per pass, 24000rpm.