Benutzer-Werkzeuge

Seitenleiste

Inhaltsverzeichnis

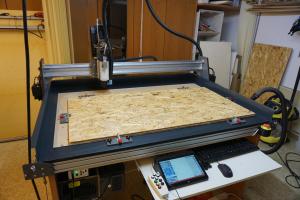

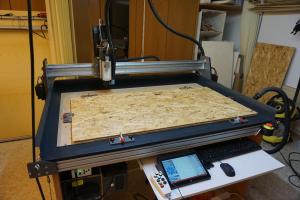

HTD-3M Belt Mill

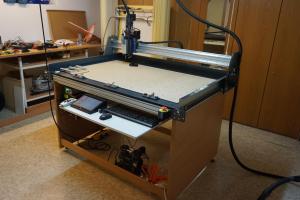

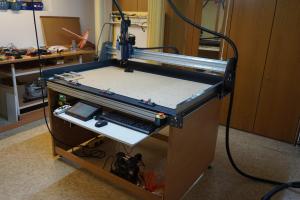

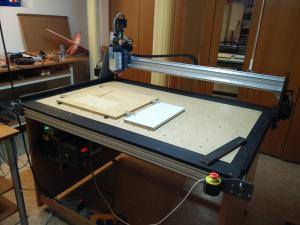

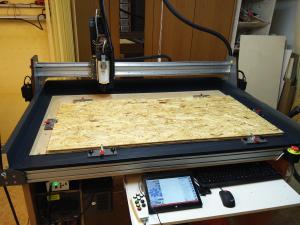

After using my enlarged eShapeoko for some years i wanted to build something larger and a bit more powerful. In between i had made some experiments with a large but very light coreXY portal usable for foam sheets and thin plywood and balsa. That was fun, but i wanted to have something more rigid and powerful.

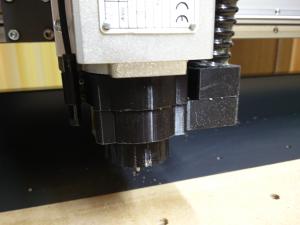

In Summer 2017 i bought some supported rails with 1500mm and 1000mm - just because they were so cheap at banggoods EU warehouse. Once they arrived i started planing a portal mill around them ;_). Due to the large size, i opted on using HTD3 timing belts with 15mm width instead of ball screws for X and Y. Timing belts worked fine on my other machines and ball screws in that length would either need to be very thick or make use of rotating nuts which would have been to expensive. For the Z Axis i bought 2 MGN 12 linear rails with 4 carriages and a 1204 ball-screw from china. After experimenting with some very cheap NEMA23 Motors, i changed my mind and bought 4 JMC NEMA23 closed loop steppers with integrated drivers. That should give enough power and ease all the cableling as is does not require an extra set of stepper drivers. Now that the machine had powerful motors, i wanted to have a powerful spindle as well. with some luck i found a good aliexpress deal for a 1.5kw air cooled spindle with inverter.

After using my enlarged eShapeoko for some years i wanted to build something larger and a bit more powerful. In between i had made some experiments with a large but very light coreXY portal usable for foam sheets and thin plywood and balsa. That was fun, but i wanted to have something more rigid and powerful.

In Summer 2017 i bought some supported rails with 1500mm and 1000mm - just because they were so cheap at banggoods EU warehouse. Once they arrived i started planing a portal mill around them ;_). Due to the large size, i opted on using HTD3 timing belts with 15mm width instead of ball screws for X and Y. Timing belts worked fine on my other machines and ball screws in that length would either need to be very thick or make use of rotating nuts which would have been to expensive. For the Z Axis i bought 2 MGN 12 linear rails with 4 carriages and a 1204 ball-screw from china. After experimenting with some very cheap NEMA23 Motors, i changed my mind and bought 4 JMC NEMA23 closed loop steppers with integrated drivers. That should give enough power and ease all the cableling as is does not require an extra set of stepper drivers. Now that the machine had powerful motors, i wanted to have a powerful spindle as well. with some luck i found a good aliexpress deal for a 1.5kw air cooled spindle with inverter.

Well, getting father and buying a house took most of my time since the first parts arrived, so that it took nearly a year before i really started to assemble the machine - the good thing is that now that the machine is finished i have some space to put it ;_) Would have been quite crowded in the small basement of my former flat, now i have ~90 square meters of basement to play around.

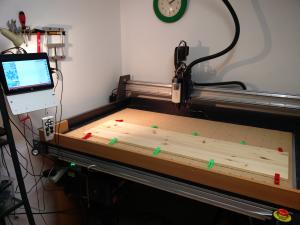

All in all everything that i planed in librecad in 2D fitted quite well. Compared to my eShapeoko it looks really huge, massive and rigid - of course not comparing it to other machines made to mill aluminum and steel.

Total price including the 1.5KW Spindle summed up at ~1000€. All listed prices are what i payed for (most incl shipping). Most of the stuff was bought over a longer time period waiting for items to go on sale or being available in the EU stock. If you have some time and do some research you will find them for a similar price i guess. You can save some money on cheaper Stepper Motors, but the JMC Closed Loop are definitely worth their Money.

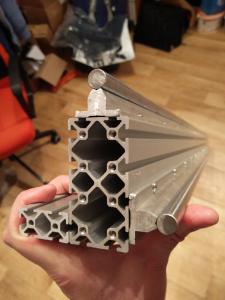

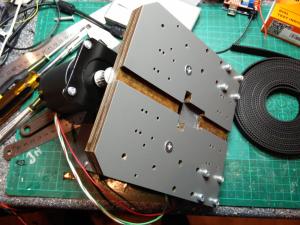

XY Portal

- HPL Fassadenplatten 8mm, or check ebay Kleinanzeigen 1000x500x8mm 2×28€

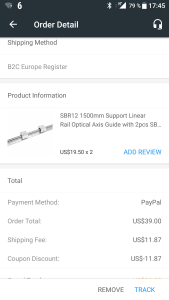

- SBR12 1500mm Support Linear Rail Optical Axis Guide with 2pcs SBR12UU Bearing Blocks special offer in the EU warehouse. US$19.50×2

- SBR20 1000mm Linear Rail Optical Axis Guide with 2pcs SBR20UU Bearing Blocks special offer in the EU warehouse. US$20×2

- Profile 40x80 I-Type slot 5 1500mm Portal 30€

- Profile 20x40 I-Type slot 5 1500mm Portal Back 10€

- Profile 60x60L I-Type Slot 6 2x 1000mm Sides 40€

- Profile 30x60L I-Type Slot 6 2x 1500mm Back/Front 45€

- Profile 30x60L I-Type Slot 6 3x 1280mm Table 55€

- M4 Square Nut 50pcs 2x $2

- HTD 3M Timing Pulley 15T 15mm Bore 8mm 4pcs 14$ Choose matching to your Motor shaft.

- Total ~ 420€

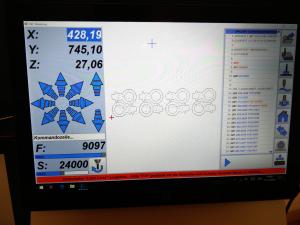

Belt-Step-Resolution calculation: GT3 Belt with 3mm pitch * 15 tooth pulley = 45mm per revolution. 45mm / 2000 steps = 0,025mm/step

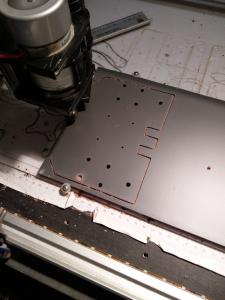

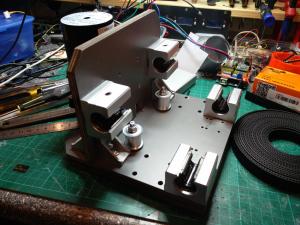

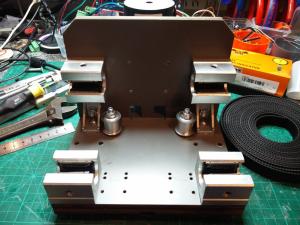

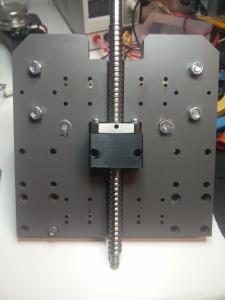

Z-Axis

- 8x10mm CNC Motor Jaw Shaft Coupler $1 Choose matching to your Motor shaft.

- Total ~ $60

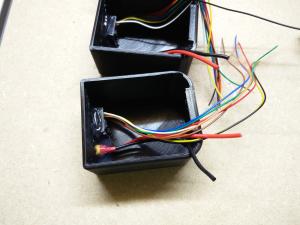

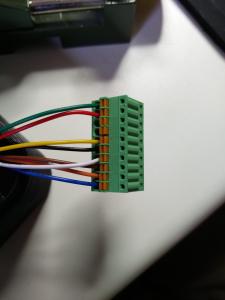

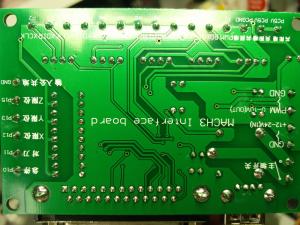

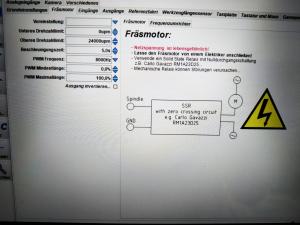

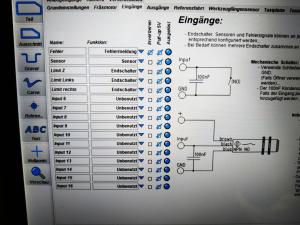

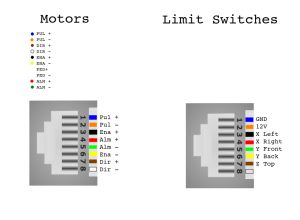

Electronics

- Cisco WS-CAC-1300W AC Power Supply 42V 27A 19€ Anschlussbelegung und Umbau thread: https://forum.mosfetkiller.de/viewtopic.php?f=2&t=63559

- JMC-iHSS57-36-20-NEMA23-2Nm-283oz-in-Integrated-Closed-Loop-Stepper set of 3 motors 210€

- Nema23 Mounting Brackets 3x 3€

- Total ~ 540€

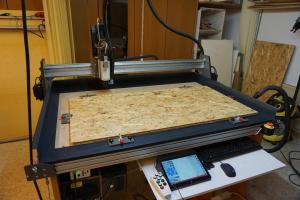

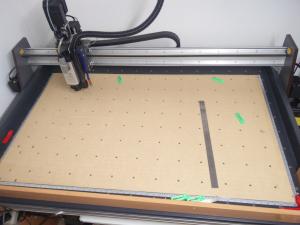

Working Plate

- 18mm MDF sheet 145x106cm

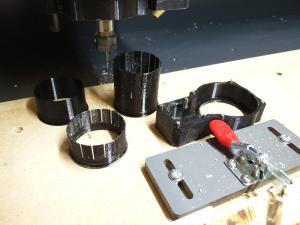

Dust Extraction

- 16 round Neodym magnets D=3mm L=10mm

- suchtion hose 1„ (~25mm inner, 30mm outer Diameter)

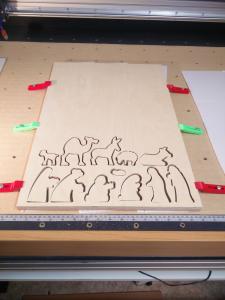

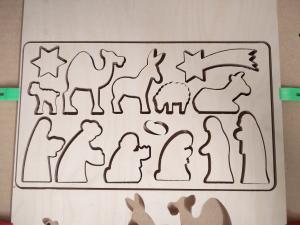

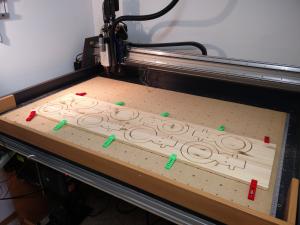

Pics

Videos

first testrun @15m/min

surface planning @10m/min

cutting OSB wood

cutting 6mm HPL, 1/8 1-flute bit, 24000rpm, 3.5mm per pass, 1000mm/min

surface planning, 30mm endmill @ 15000mm/min, 0.5m per pass

beech plywood, 1/8 1-flute bit, 24000rpm, 4.5mm per pass, 5000mm/min

Links

Ich garantiere bei meinen Bauberichten und Teilelisten keine Vollständigkeit etc...es wird aus den Teilen gebastelt die gerade herumliegen.

Bitte keine Anfragen zum Bau/Fräsen von Frames, Teilen oder sonstigen Aufträgen. Ich betreibe die Seite rein als Hobby und nutze die zur Verfügung stehende Zeit gerne für meine eigenen Projekte.

Bei einigen Projekten werde ich zu gegebener Zeit die Pläne veröffentlichen - aber auch hier lasse ich mich ungern hetzten ;-)

No waranties for completeness of any contructions, part lists etc.. I build from party i have just lying around in my workshop.

Please, No requests to buy frames, builds, etc.. I run this page in my spare-time and as hobby only. Want to keep my free time to work on my own projects - sorry

I will release the plans for some build at some point in time, but again, please don't ask for unreleased plans, i don't want to get rushed ;-)