Benutzer-Werkzeuge

Seitenleiste

Inhaltsverzeichnis

CoreXY Portal Mill/Laser

After buidling my first eShapeOKO CNC in 2012 i really liked the Makerslide approach of linear rails - just simple and cheap. Since that i always tried to build something similar, but even cheaper. I tried different stuff on my laser-engravers v1-v4 the last years.

After buidling my first eShapeOKO CNC in 2012 i really liked the Makerslide approach of linear rails - just simple and cheap. Since that i always tried to build something similar, but even cheaper. I tried different stuff on my laser-engravers v1-v4 the last years.

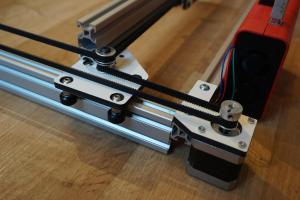

This time the idea was to build a coreXY principle portal using off-the-shelf components. As the used Bosch type 20×20 and 20×40 profiles and the GT2 belt are that cheap, id decided to go a bit bigger with 1500x1000mm rails. This gives me the opportunity - assuming the portal and my Z-Axis do the job - to cut 3/6mm DEPRON foam boards (1250×700) for my RC-Planes, maybe even soft plywood or balsa. If not, the portal will be used for something else. There is although another Laser Module lying around here…

After sourcing all needed parts and taking bolts, washers and cables from my stock i ended up at ~140€ for the whole build (without Z-Axis).

Here we go!

buildlog:

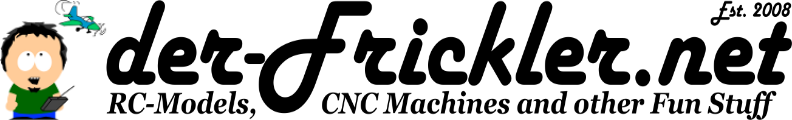

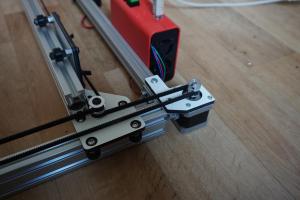

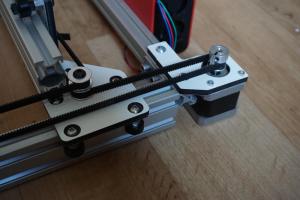

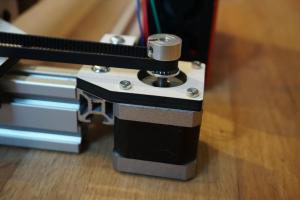

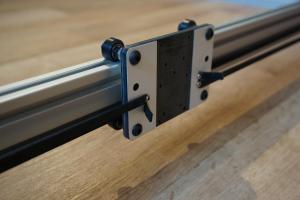

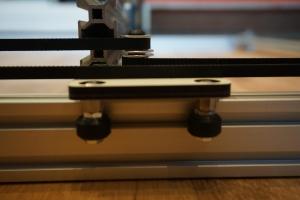

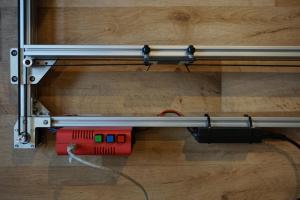

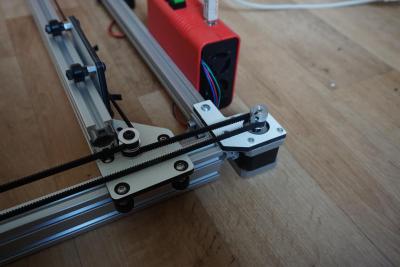

Building the portal out of 2020 and 2040 aluminum profile and matching brackets was straight forward. I was impressed of how good the small mini wheels were running on the normal cheap - non v-slot - profile. The mounts for the motors and pulleys as well as the wagons were milled out of 6mm HPL (high preasure laminate) material on my eShapeoko. Everything was screwed together with T-Slot nuts. I was aware that coreXY needed longer belts, but a bit surprised that this machine needed full 10m of Belt for a portal with 1500x1000mm size.

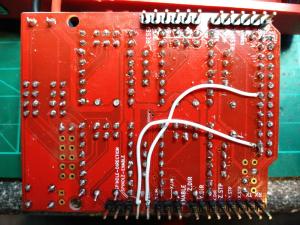

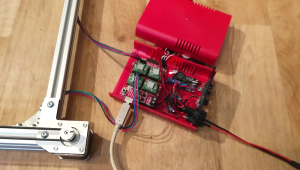

On the electronics side, the Cheap Arduino Uno with grbl shield does a great Job. GRBL 1.1 was compiled with coreXY support enabled and the homing procedure modified to home the long axis (X) first and the portal (Y) after that. First run tests with the latest UniversalGcodeSender Platform showed a max speed of ~20000mm/min. Nice ;_)

Plans: CoreXY plans as DXF drawn with librecad.

Portal

- 20x40 Profile I-Type 2x1.45m 2x 10€

- 20x20 Profile I-Type 2x1m 2x 3.20€

- M5 T-Slot Nuts $5.50

- Bunch of M5x10 M5x40 Screws, M5 Spacers and M5 Washers.

- 6mm HPL (High Pressure Laminate) for all CNC Parts.

- 10m GT2 Belt $10

- 16T GT2 Pulleys 5mm for NEMA17, 6mm for Pollin NEMA23 $4

Mechanics Total: ~85€

Electronics

- Limit Switches $2.6

- 48mm NEMA 17 Motors 2x $12 planed: Nema 23 Pollin Motors have 6mm Axis!! 2x 10€

Electronics Total: ~50€

- Modding the CNC/GRBL Shield for grbl Versions >=0.9 (exchange Z-limit and spindle enable pin): https://github.com/grbl/grbl/wiki/Connecting-Grbl

- Compiling GRBL with coreXY Settings https://github.com/grbl/grbl/blob/master/grbl/config.h#L145

Tools

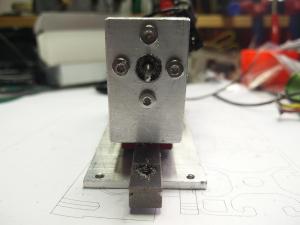

Z-Axis and Mill

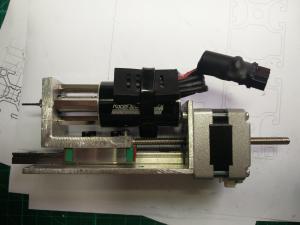

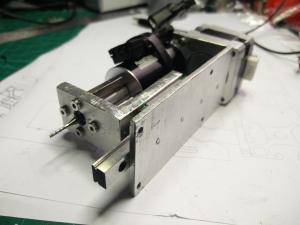

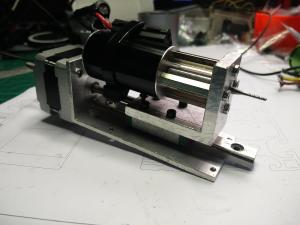

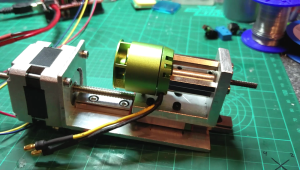

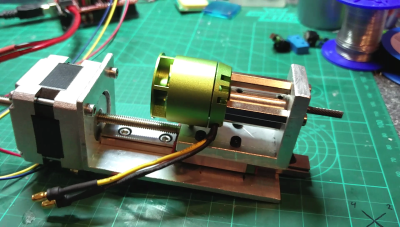

Small Z-Axis with RC Heli Motor as Spindle.

Small Z-Axis with RC Heli Motor as Spindle.

4000kv Heli Motor$14 4000kv Car Motor $14- XM30 A ESC $13 flashed with BLHeli, PWM input enabled, damped light disabled.

- MGN9 Linear Rail $10

Laser

…coming

3.5W Laser Modul …was very cheap while the banggood anniversary.

Pics

Videos

testing the wagons

testing the portal

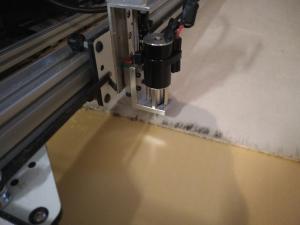

testing the Z-Axis

First Test of the machine with Z-Axis and Spindle installed.

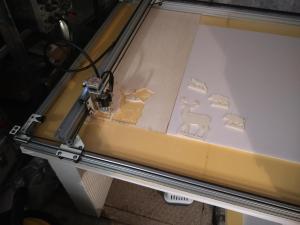

Cutting the Vacuum Table out of Styrodur. Feed 10000mm/min Depth 15mm

Cutting some 4mm Plywood. Feed 1000mm/min depth 4mm. Vacuumtable holds the plywood.

Software / Firmware

GRBL 1.1 Settings:

Grbl 1.1f ['$' for help] >>> $$ >>> $G >S100:ok >S0:ok $0=10 $1=25 $2=25 $3=1 $4=0 $5=0 $6=0 $10=17 $11=0.010 $12=0.002 $13=0 $20=1 $21=1 $22=1 $23=3 $24=1000.000 $25=10000.000 $26=250 $27=2.000 $30=1000 $31=0 $32=0 $100=40.000 $101=40.000 $102=200.000 $110=15000.000 $111=15000.000 $112=1000.000 $120=400.000 $121=400.000 $122=10.000 $130=1310.000 $131=760.000 $132=400.000

Ich garantiere bei meinen Bauberichten und Teilelisten keine Vollständigkeit etc...es wird aus den Teilen gebastelt die gerade herumliegen.

Bitte keine Anfragen zum Bau/Fräsen von Frames, Teilen oder sonstigen Aufträgen. Ich betreibe die Seite rein als Hobby und nutze die zur Verfügung stehende Zeit gerne für meine eigenen Projekte.

Bei einigen Projekten werde ich zu gegebener Zeit die Pläne veröffentlichen - aber auch hier lasse ich mich ungern hetzten ;-)

No waranties for completeness of any contructions, part lists etc.. I build from party i have just lying around in my workshop.

Please, No requests to buy frames, builds, etc.. I run this page in my spare-time and as hobby only. Want to keep my free time to work on my own projects - sorry

I will release the plans for some build at some point in time, but again, please don't ask for unreleased plans, i don't want to get rushed ;-)